A fire fighting water pump is a vital component of a property’s fire suppression systems. Found in manufacturing facilities, apartment complexes, airports, hospitals, power plants and commercial buildings, fire pumps are responsible for supplying water at the proper pressure to sprinklers and hose standpipes when the system is activated. Properly selecting and specifying a fire pump is critical to maintaining code compliance standards. A fire protection specialist can help determine what size, type and capacity of pump is needed for the particular building.

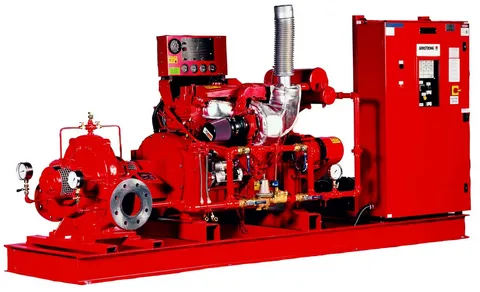

Fire pump selection starts with evaluating the available water pressure and flow at a property. NFPA 20 and other regulations provide guidelines on minimum requirements for the pressure and flow of a fire pump. Typical pumps are centrifugal or turbine style with an electric motor or diesel engine.

Pump size and capability is typically determined by a property’s specific needs, the occupants of the building and the size of the piping used to connect the fire pump. For example, a high-rise office building may have large sprinkler demands and multiple hose standpipes while an apartment complex may only require a small system for the entire building.

Another important consideration when selecting a fire pump is the location of the fire department connection (FDC). The FDC should be located on the discharge side of the fire pump to prevent damaging conditions from arising within the pump. An upstream FDC causes excessive velocities that increase water turbulence and often cause the fire pump to exceed its maximum suction pressure rating. The excessive velocities also can erode the pump’s internal components causing costly repairs.

Once the pump is selected, a flow test must be performed on the fire hydrant that will be supplying water to the fire suppression system. The resulting data is critical to understanding the required flow and pressure of the fire pump as well as how it will interact with the existing water supply.

During the flow test, an electrical motor is turned on to drive a shaft that powers an impeller and creates a water flow. The result is a graph that shows the pressure and flow capabilities of the fire pump as the discharge valve is opened and closed from closed to open. Pump curves are not a standard feature on all fire pumps and should be requested from the manufacturer when selecting a new pump.

Many fire pumps are advertised with both a maximum pressure and a maximum flow rate. However, a pump that has the ability to deliver both will not do so simultaneously as a centrifugal pump cannot produce both at the same time due to friction loss. Friction loss occurs as water runs through hoses and couplings that rub against each other as they move through the system. The amount of friction that is lost is reflected in the nozzles that are chosen for a given application and gallons per minute (GPM) flow requirement.